The company's history

The DARTEX Company was created in 1992. Initially we worked as a production company but since 1998 we have been sewing bathing and beach suits for our clients. Years of experience and implementation of new production technologies have enabled us to become a well-known brand and gain customers’ trust.

Thanks to the development of our company and the established position in the sector we can continuously obtain new contacts. Therefore in 2012 we modernized the company and we extended the scope of our services by sewing other knitted garments, such as comprehensive cycling clothing, leggings, T-shirts, polo shirts, tracksuits, hooded sweatshirts, blouses, skirts and dresses, etc.

From the beginning, our main focus is a customer’s satisfaction and thanks to our professional staff we are able to support and assist our clients on each production stage. We own a modern machine park, which we are constantly developing and improving to meet the expectations of our most demanding customers. Thanks to the acquired experience DARTEX can guarantee that the order will be completed on time and with the highest quality.

We are environmentally friendly!

For our current and future clients, it is important that their clothes are produced in an ethical manner, with high work culture and respect to the planet. DARTEX is responsible, pro-ecological, family business with high social and environmental awareness. This is the reason why we decided to invest in a renewable energy source - photovoltaics, which popularity is growing rapidly around the world.

Electric energy from solar radiation is a clean energy. During its production there are no emissions of many substances harmful to health, such as: carbon dioxide, carbon monoxide, nitric oxide, sulfur oxide, etc. Contrary to conventional electric station, during the solar energy production process, there are no usage of drinking water, or generation of noise. Moreover, photovoltaic installations do not affect the surrounding flora and fauna. Solar panels can be fully recycled after they are used because they are entirely composed of aluminum. Another benefits of this solution are cost reduction, the willingness to be an independent employer who can store the produced energy and be more competitive on the local market.

Our awards

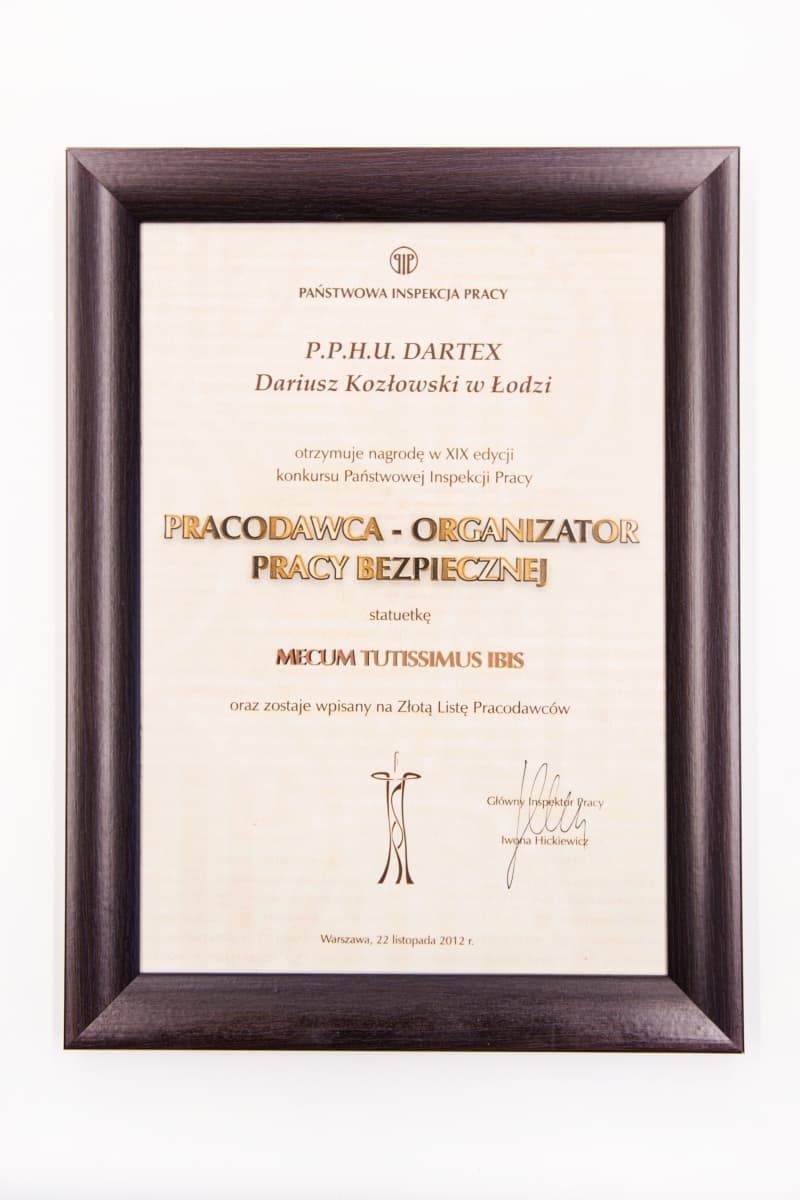

Furthermore, we are creating a friendly environment for our employees, which is confirmed by the awards received from the Labour Inspectorate in competitions for “Employer of the Safe Work Organization” within the category of companies with up to 50 employees.

- 2010– 1st place in the 17th edition of the competition “The Employer of the Safe Work Organization 2010”

- 2012 – 1st place in the 19th edition of the competition „The Employer of the Safe Work Organization 2012” , the Statuette Mecum Tutissimus Ibis, the Entry into the Golden List of Employers